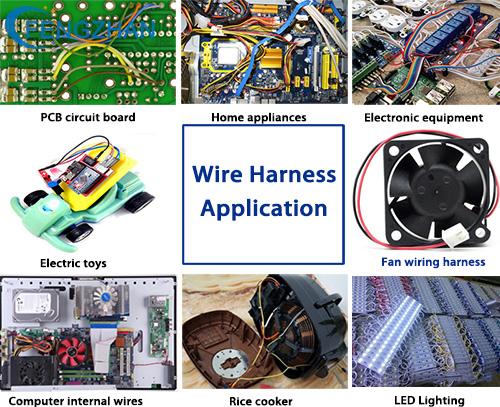

Electronic wiring harness products are generally used in various fields, but some bad factors in the harsh environment may cause the electronic wiring harness to malfunction, so what are the bad environmental factors that can damage the electronic wiring harness? The following is to share with you the environmental hazards that lead to the failure of the electronic wiring harness.

Moisture and dust factors:

One of the reasons that easily cause the failure of the electronic wiring harness is the intrusion of moisture, dust and pollutants. For example, in a humid environment, when water and electricity come into contact with each other, it will cause a short circuit between the electronic wiring harness and the device. Moreover, as time goes by, dirt or dust entering the electronic wiring harness will accumulate to form an insulating layer, which will cause the quality of the connection of the electronic wiring harness to deteriorate, thereby causing connection failure.

In addition, chemical substances or surfactants may be introduced when cleaning the electronic wiring harness, which will corrode electrical conductors, reduce their ability to carry current, and may cause malfunctions.

Shock and vibration factors:

Electronic wiring harnesses may also suffer from physical damage failure problems, which are usually affected by shock and vibration factors. These environmental factors may cause electronic wiring harness mechanical failure or electrical connection damage. The metal shell can provide the electronic Wire Harness with impact strength, and the thermoplastic shell can resist the corrosion of the electronic wire harness, and has flame retardancy and chemical resistance.

Other environmental hazards:

In addition to dust and moisture, extreme temperatures can also damage the electronic wiring harness, such as the high temperatures experienced in many industrial processes or mining industries. The high ambient temperature underground will cause the electronic wiring harness to experience extreme temperatures, frequently from low to high. Circulation can also cause malfunctions in the electronic wiring harness. Moreover, when the electronic wiring harness is used at a temperature below zero, it is necessary to deal with the problem of icing. As the water freezes, it will expand and generate a lot of force, which may damage the electronic wiring harness because of the extra weight of ice. Put pressure on the electronic wiring harness.

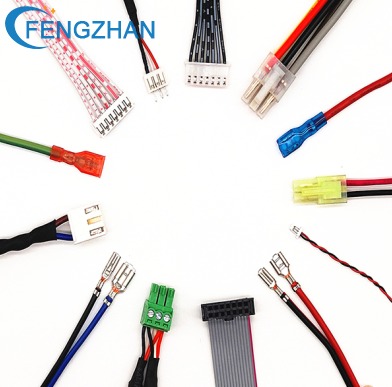

Dongguan Fengzhan Electronic Technology Co., Ltd. provides customers with high-quality wiring harnesses and recommends suitable temperature- and cold-resistant wires. The wiring harness can be customized according to customer requirements.

Contact: Lynn Long

Phone: 0086 13640200141

E-mail: lynn@fzwires.com

Whatsapp:0086 13640200141

Add: No. 19, Minye Street, Zhufoling Community, Tangxia Town, Dongguan City, China